YMTC Ti600 1TB Test Report

| Model Name | Firmware Version | TMT1 (℃) | TMT2 (℃) | |

|---|---|---|---|---|

| Ti600 | ZHITAI Ti600 1TB | ZTA23001 | 109 | 117 |

1. Half Drive Fill

Test Procedure

- Format the DUT.

- Fill 50% of DUT’s capacity.

Expected Outcomes

- Monitor performance shifts from SLC to QLC.

- Maintain stable SLC write performance, aiming for the highest possible results.

- Maintain stable QLC write performance, aiming for the highest possible results.

Results

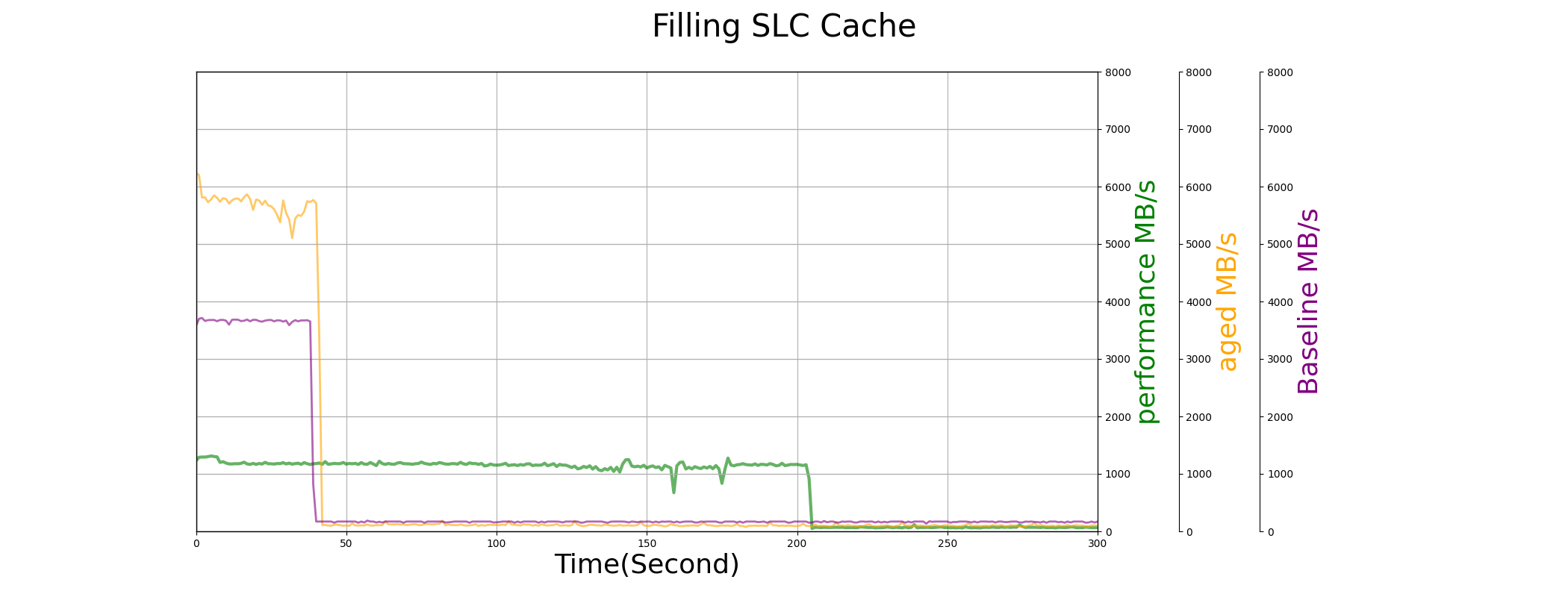

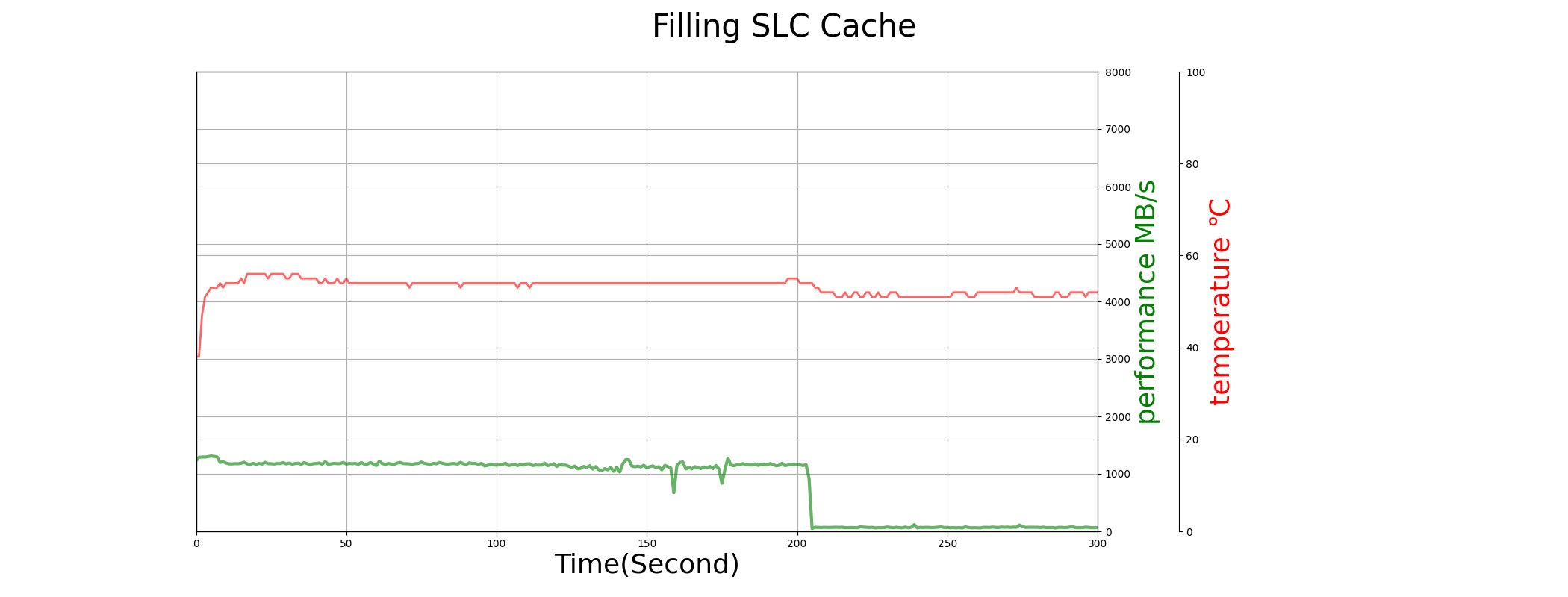

The observed SLC write performance varied significantly during tests. At times, it was capped at approximately 1GB/s, suggesting potential bottlenecks or limitations. In other instances, the SLC performance reached speeds up to 6GB/s, indicating optimal functionality. Conversely, the QLC write performance consistently showed slower rates, which may require further investigation to determine the underlying causes.

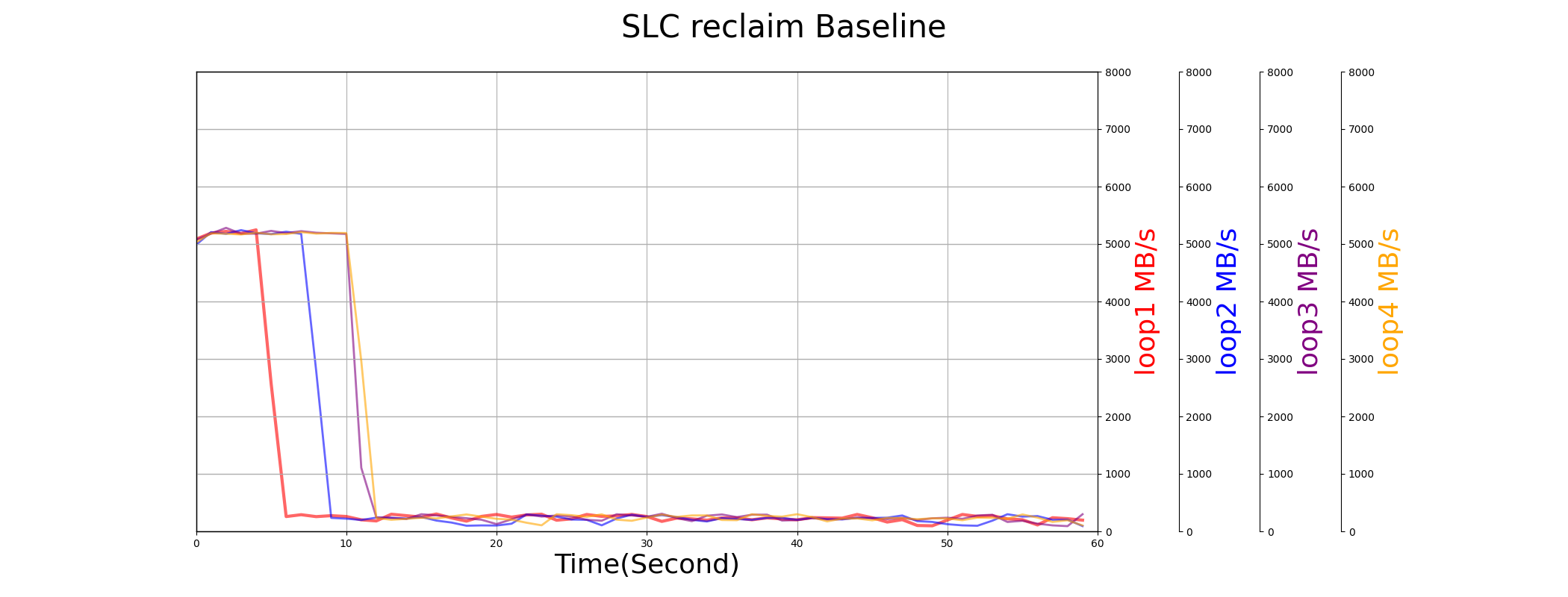

2. SLC Reclaim

Test Procedure

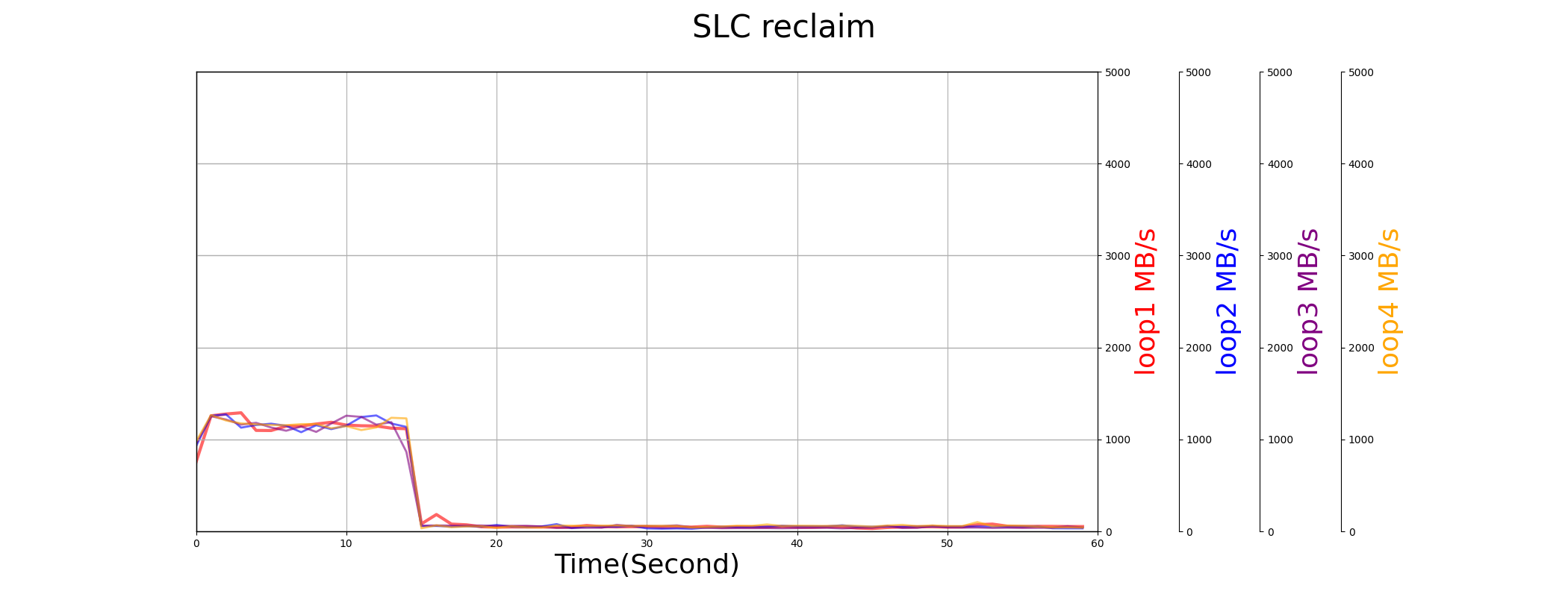

- Loop1: Idle for 1 minute, followed by sequential writing for 1 minute.

- Loop2: Idle for 2 minutes, followed by sequential writing for 1 minute.

- Loop3: Idle for 3 minutes, followed by sequential writing for 1 minute.

- Loop4: Idle for 4 minutes, followed by sequential writing for 1 minute.

Expectations

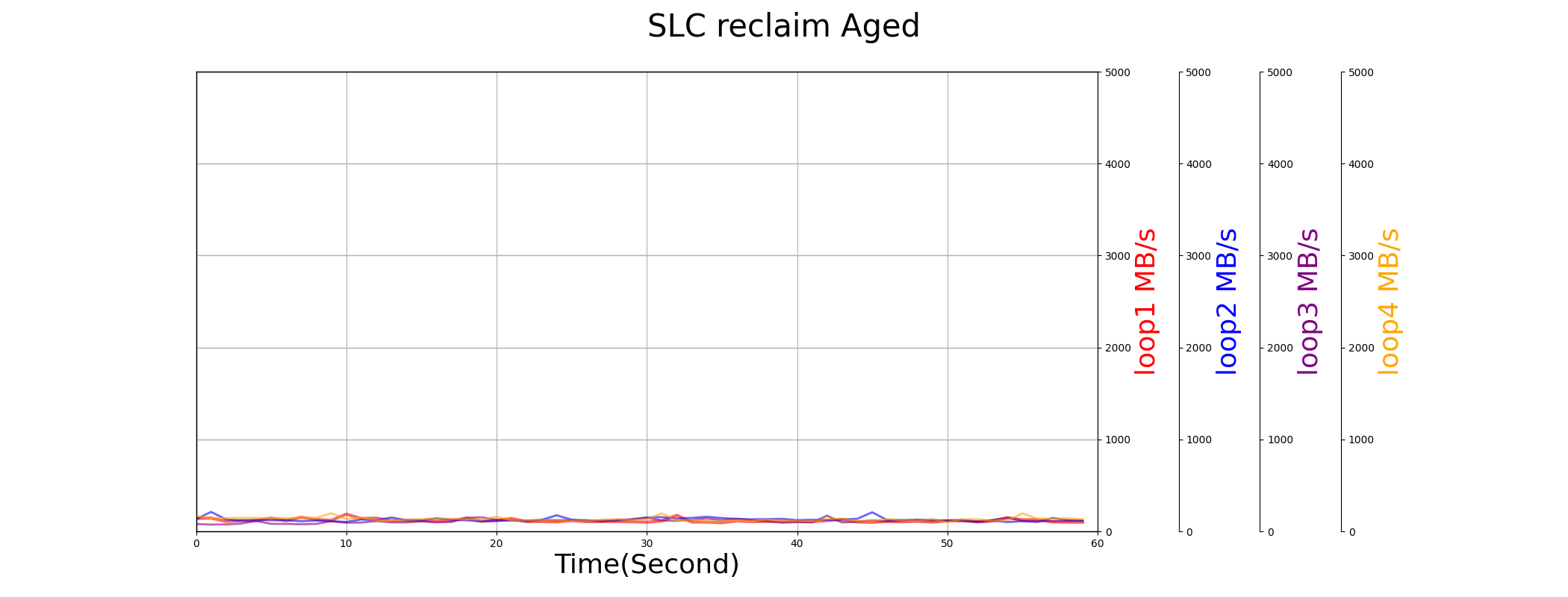

- Monitor and record the SLC write performance during each loop.

- Expect to see an extended SLC write stage in successive loops as the idle duration increases, indicating effective SLC reclaim.

Results

The SLC cache was effectively reclaimed in each loop. However, no increase in SLC cache availability was observed despite longer idle periods. Notably, after undergoing DW200 aging, the SLC cache was fully retired, leading to a permanent shift to the slower QLC storage.

3. Sequential Speed

Test Procedure

- Fill 10% of the drive’s capacity.

- Measure sequential read and write performance.

- Fill 50% of the drive’s capacity.

- Measure sequential read and write performance again.

Expectations

- The sequential read performance should remain consistent regardless of the capacity filled.

- Both read and write performance should not degrade due to aging.

| 10% fill read MB/s | 50% fill read MB/s | 10% fill write MB/s | 50% fill write MB/s | |

|---|---|---|---|---|

| Ti600 | 4686.984 | 1344.076 | 3995.418 | 717.763 |

| Aged | 4584.431 | 773.620 | 4008.457 | 108.543 |

| Baseline | 5227.481 | 4718.039 | 3852.158 | 425.910 |

Results

When the drive was filled to 10% capacity, both read and write performance were optimal. However, upon filling the drive to 50% capacity, there was a significant drop in performance. Similarly, performance declined substantially as the drive aged.

4. Random IOPS

Test Procedure

- Fill 10% of the drive’s capacity.

- Measure random read and write performance.

- Fill 50% of the drive’s capacity.

- Measure random read and write performance again.

Expectations

- The random read performance should remain consistent regardless of the capacity filled.

- Both random read and write performance should not degrade due to aging.

| 10% fill read K | 50% fill read K | 10% fill write K | 50% fill write K | |

|---|---|---|---|---|

| Ti600 | 180.255 | 179.722 | 57.725 | 23.008 |

| Aged | 179.210 | 69.924 | 58.217 | 22.208 |

| Baseline | 189.532 | 195.910 | 51.637 | 53.204 |

Results

The performance when the drive was filled to 10% capacity met expectations, showing good random read and write capabilities. However, there was a noticeable decline in performance after filling the drive to 50% capacity and as the drive aged.

5. QD1 Latency

Test Procedure

- Fill 10% of the drive’s capacity.

- Test random 512B QD1 read and write for 99.9% latency.

- Fill 50% of the drive’s capacity.

- Test random 512B QD1 read and write for 99.9% latency again.

Expectations

- The read latency should remain consistent, unaffected by the capacity filled.

- Both read and write latencies should not degrade due to aging.

| 10% fill read 99.9% latency ms | 50% fill read 99.9% latency ms | 10% fill write 99.9% latency ms | 50% fill write 99.9% latency ms | |

|---|---|---|---|---|

| Ti600 | 9.926 | 5.004 | 6.946 | 11.239 |

| Aged | 5.887 | 5.309 | 0.744 | 4.802 |

| Baseline | 0.173 | 0.171 | 1.759 | 1.824 |

Results

The test results showed that the read latency is significantly prolonged across different fill levels and aging conditions, with instances exceeding 100ms and reaching up to 1 second.

6. Low Loading Latency

Test Procedure

- Set the IOPS to 10 and measure the 99.9% latency for reads.

- Set the IOPS to 100 and measure the 99.9% latency for reads.

- Conduct a read/write mix with 90% reads at a fixed 1000 IOPS and measure the 99.9% latency.

- Conduct a read/write mix with 50% reads and measure the 99.9% latency.

- Replay the JEDEC client workload and record the replay duration time.

Expectations

- The lower the latency, the better.

- Latencies exceeding 300ms are considered detrimental to user experience.

| 10 IOPS 99.9% read Latency (ms) | 100 IOPS 99.9% read Latency (ms) | mix IO 99.9% Latency (ms) | 90% mix 99.9% Latency (ms) | JEDEC workload replay (s) | |

|---|---|---|---|---|---|

| Ti600 | 155.115 | 9.779 | 361.865 | 134.980 | 6174.751 |

| Aged | 139.606 | 9.984 | 123.650 | 139.809 | 12688.973 |

| Baseline | 4.062 | 0.191 | 154.823 | 13.235 | 2651.787 |

Results

The latency exceeded 100ms in several test cases, indicating longer than desired response times. Additionally, the JEDEC client workload replay duration was notably lengthy, with even more prolonged times observed in aged conditions.

7. Low Power State

Test Procedure

- Format the Device Under Test (DUT).

- Transition the DUT to Power State 4 (PS4) using the

setfeaturescommand. - Measure power consumption in PS4.

- Send IO commands to transition out of PS4.

- Measure the latency to exit from PS4.

- At a fixed 10 IOPS, measure the power consumption under an idle/active mixed workload.

Expectation

- Lower power consumption is preferable.

| idle power mW | PS4 exit Latency (us) | 10 IOPS power (mW) | |

|---|---|---|---|

| Ti600 | 1.7 | 37841.4 | 927.545 |

| Aged | 0.0 | 8125.1 | 0.000 |

| Baseline | 2.5 | 25070.8 | 250.728 |

Results

The power consumption while idle was commendably low. However, during low-loading workloads that mixed idle and active states, the power consumption was notably higher.

8. Trim Efficiency

Test Procedure

- Format the DUT and fill it to 90% capacity.

- Measure sequential write performance.

- Trim the first 50% of the DUT’s capacity.

- Measure the average latency of the executed trim commands.

- Measure sequential write performance again after the trim.

Expectation

- The latency for trim operations should be as short as possible.

- Sequential write performance should improve following the trim operation.

- Aging should impact the efficiency of trim performance.

| Average Latency (ms) | performance before trim (MB/s) | performance after trim (MB/s) | |

|---|---|---|---|

| Ti600 | 7.646 | 558.788 | 1913.728 |

| Aged | 8.149 | 125.320 | 131.708 |

| Baseline | 3.839 | 695.887 | 2393.860 |

Results

During the aged stage, the lack of SLC cache significantly impeded performance. As a result, sequential write speeds before and after the trim operation were both notably slow.

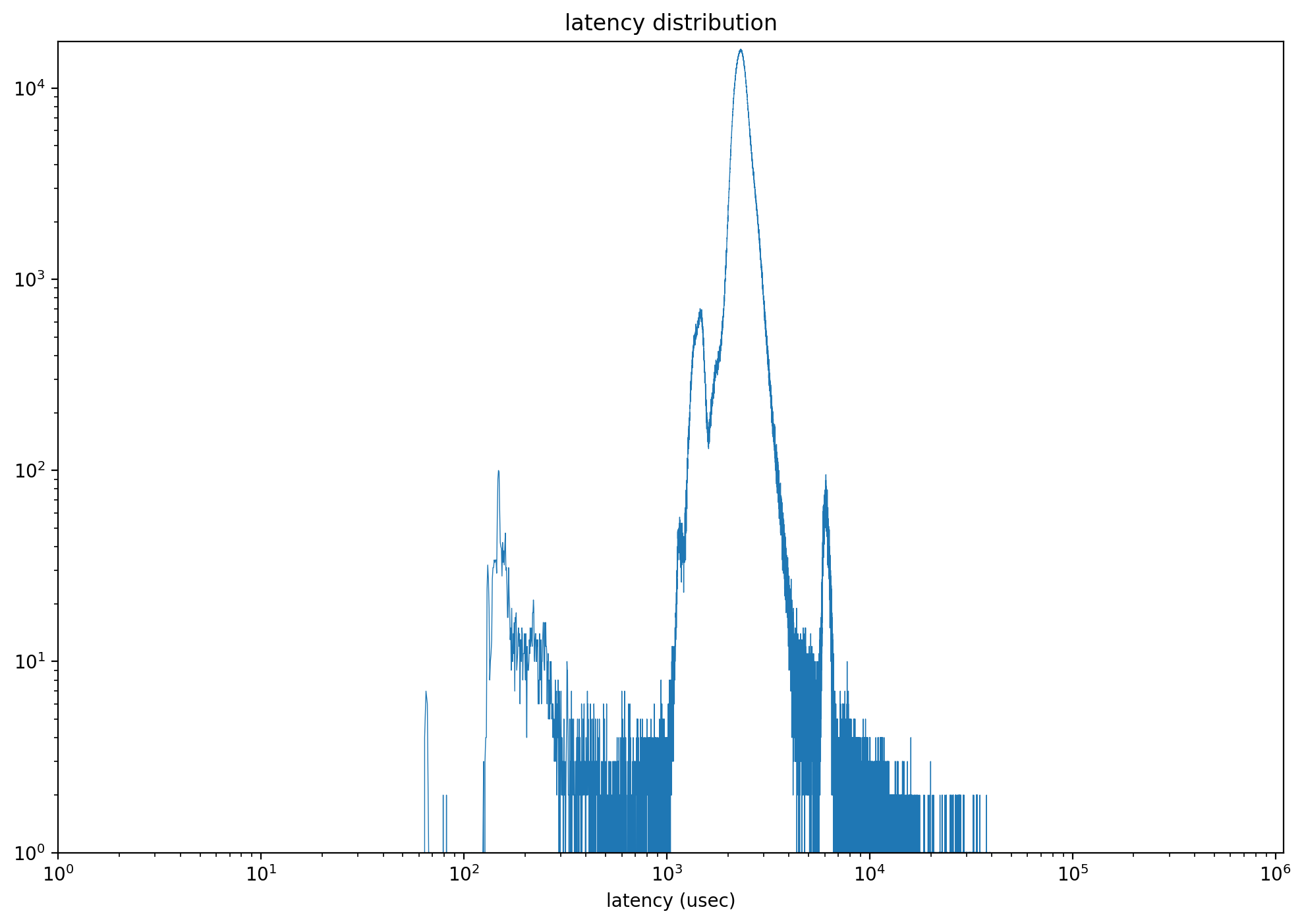

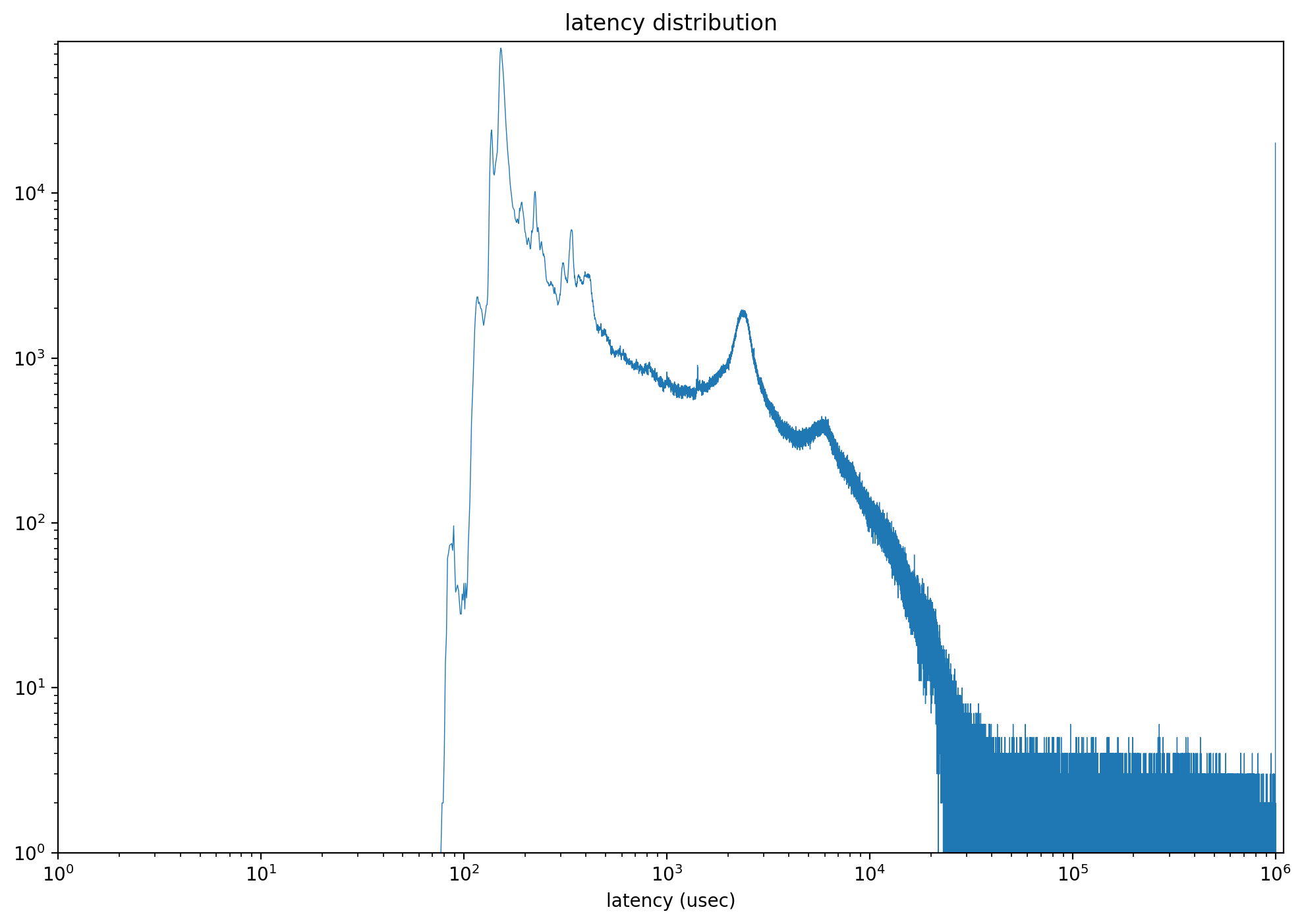

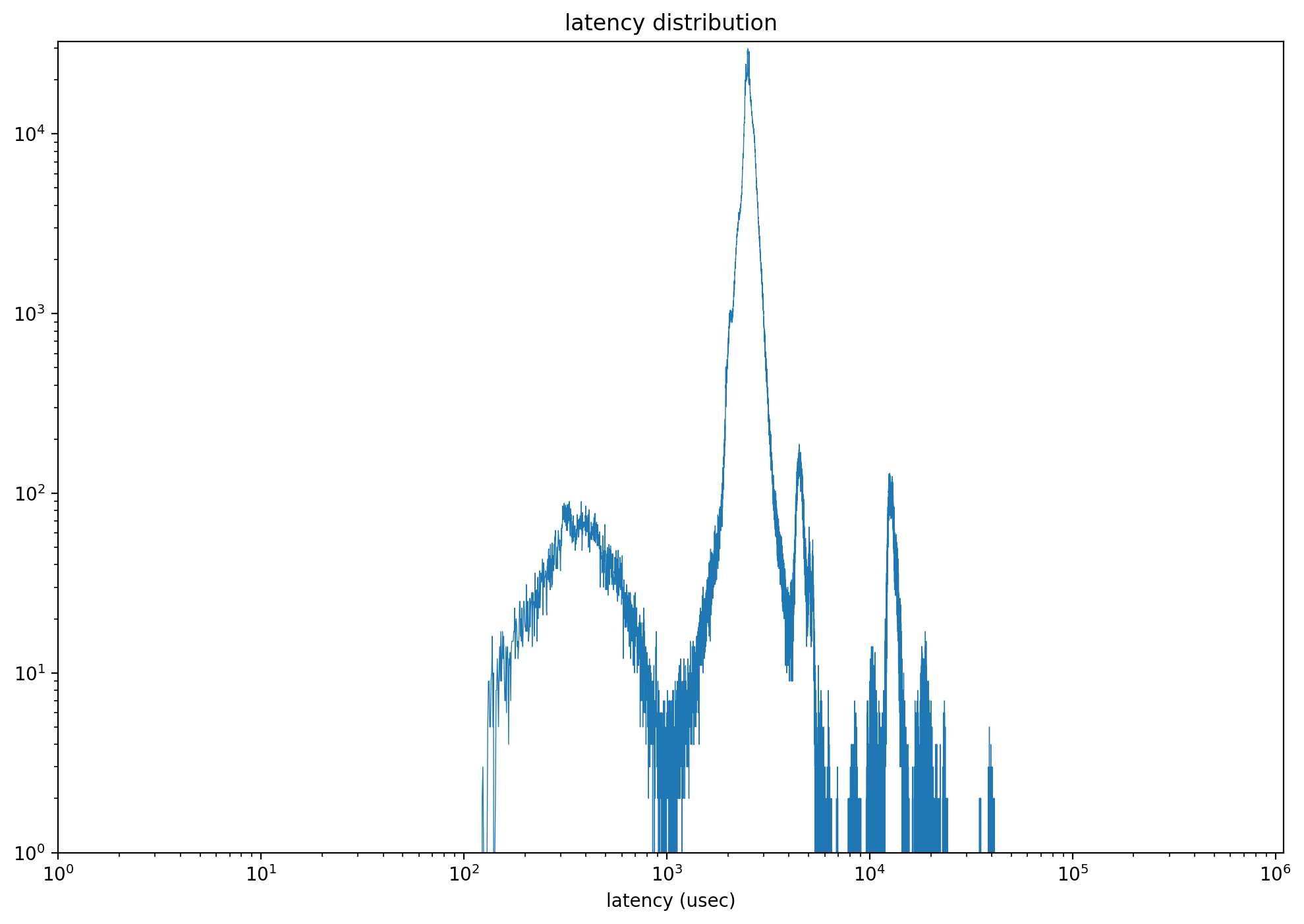

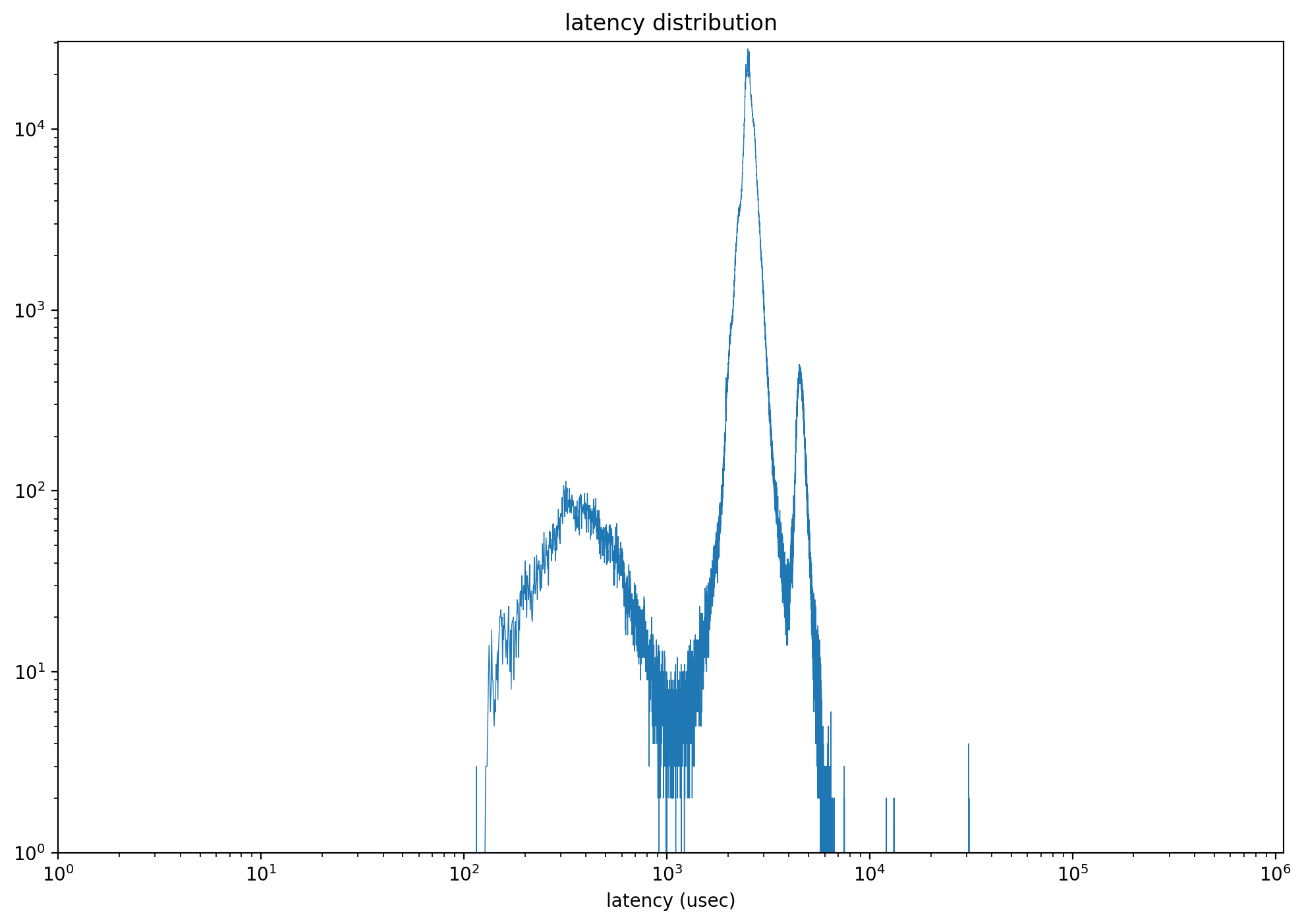

9. Data Retention

Test Procedure

- Fill the entire drive 300 times and age it to its End of Life (EOL).

- Format the DUT.

- Fill the entire drive again.

- Power off the device.

- Store the DUT at room temperature for two months.

- Power on the DUT.

- Read the entire drive and measure the distribution of read latencies.

Expectation

- The final read operation should complete successfully and quickly.

- There should be no read latencies longer than 100ms.

| distribution month 0 | distribution month 2 | |

|---|---|---|

| DUT |  |

|

| Baseline |  |

|

Results

The test revealed excessive read latencies, with many instances exceeding 100ms, and some even reaching 1 second.

10. Other Tests

The following table summarizes the results of various additional tests conducted to assess different aspects of the Device Under Test (DUT). These tests evaluate the DUT’s conformance to standards, resilience to power on sequences, signal integrity (saw diagram), wear leveling efficiency, IO stress handling, and performance after aging.

| Item | Result |

|---|---|

| Conformance | PASS |

| Power On | PASS |

| Saw Diagram | PASS |

| Wear Leveling | PASS |

| IO Stress | PASS |

| Aging | PASS |

11. Summary

The YMTC Ti600 1TB SSD was rigorously tested across a range of conditions, assessing its sequential and random read/write capabilities, latency, power efficiency, trim functionality, and data retention.

Strengths:

- Consistent SLC Performance: The SSD excels at lower capacity usage, showcasing robust sequential and random operations at 10% fill.

- Effective Power Management: It demonstrates low idle power consumption, ideal for energy-sensitive applications.

- Reliability: It successfully passed all conformance, stress, and aging tests, proving its durability under standard conditions.

Weaknesses:

- Performance Under Load: Performance drops significantly at 50% capacity and as the device ages, indicating limitations in maintaining output under extended use.

- Latency Issues: Notable latency spikes in low-load and data retention tests could affect performance in latency-critical tasks.

- SLC Cache Efficiency: SLC cache did not expand with increased idle time and was entirely depleted with aging.

- Trimming Inefficiency: Post-trim performance improvements are negligible in aged states, highlighting diminished recuperative capabilities.

- Data Retention Concerns: Extended latencies observed during data retention tests raise questions about long-term data stability.